The best mobile home demolition doesn’t happen by wishful thinking—it happens by choosing the right method, planning the exit, and working with physics, not against it. The right approach balances structure, site, rules, and your tolerance for cost, dust, noise, and paperwork. Choose wisely and the home comes down cleanly like a zipper; choose poorly and you’re left with delays, rising costs, and endless headaches.

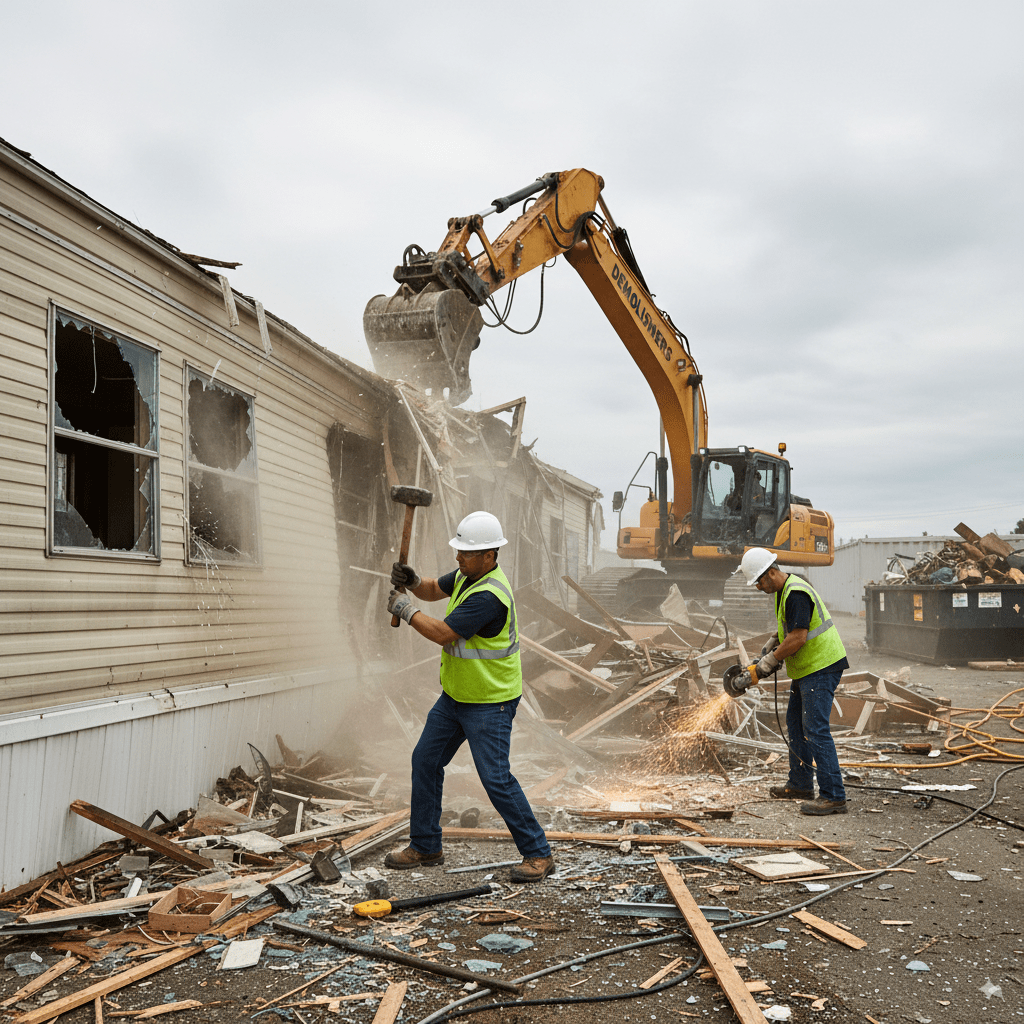

Mechanical Demolition with Heavy Machinery

This is the workhorse. An excavator or skid steer does in hours what an army of hammers can’t do in days.

How it runs: Utilities confirmed dead. Add-ons detached. The operator bites the roof, folds walls inward, lifts floor sections, and stages debris for fast loading. Clean, controlled collapses—no hero swings.

Where it shines:

- Tight timeline, clear access, and a straightforward single- or double-wide.

- You want predictable hours and an invoice that behaves.

Pros: Speed, cost control, fewer laborers, and a tidy site when paired with on-site sorting (steel chassis to scrap, mixed C&D to the container).

Cons: Needs room to maneuver. Soft lawns, narrow park lanes, and low wires slow it down. You still respect dust, nails, and neighbors.

Mechanical is the default because it’s adult: fast enough, safe enough, and priced like a plan, not a dare.

Deconstruction for Salvageable Materials

This is demolition with manners. Instead of turning everything into confetti, you pull it apart to keep value intact.

How it runs: Salvage first—appliances (after refrigerant recovery), doors, windows, fixtures, copper, clean lumber. Then careful panel removal, selective framing takedown, and tidy stacks for resale, donation, or reuse.

Where it shines:

- You’ve got resale/donation outlets and time to monetize materials.

- Local disposal is expensive and you want to shrink the landfill bill.

- Historic or specialized finishes deserve a second life.

Pros: Highest salvage value, smallest landfill footprint, neighbors think you’re civilized.

Cons: Slower, more labor, more staging, more coordination. If the unit is moldy, waterlogged, or built from lowest-tier materials, salvage value falls off a cliff.

Think of deconstruction as revenue recycling: every pound you save on tipping fees is a pound you don’t pay to bury.

Implosion Techniques for Safe Demolition

Explosives make viral videos; they rarely make sense for mobile homes.

Reality check: Mobile homes are light, close to the ground, and surrounded by other things you’d rather not rattle. True implosion requires licensed blasting engineers, extensive permitting, exclusion zones, insurance acrobatics, and months of planning—for structures that weigh and anchor like real buildings.

Where it might appear: Remote training grounds, specialized projects, or film sets with professionals running the show.

Pros: Spectacle, precise collapse on massive, rigid structures.

Cons: Overkill in 99.9% of mobile home cases. Regulatory friction, cost, public safety complexity. Not a DIY path. Not a “call a buddy” path. A “call a licensed blasting contractor and a lawyer” path.

For mobile homes, skip the fantasy. Use mechanical collapse or deconstruction and keep your eyebrows.

Controlled Burning Where Permitted

Yes, sometimes a fire department training burn is allowed. Most of the time, it’s not—and for good reason.

What “permitted” actually means: Written approval from the fire authority, verified utility disconnects, documented removal of hazardous materials (asbestos, lead-painted components, certain roofing, flooring, duct wraps), weather/air-quality greenlight, water supply on scene, trained personnel in command. This is not a shortcut; it’s a training event that occasionally aligns with your demo.

Where it shines: Rural jurisdictions with clear training-burn programs and a structure that’s been properly abated and stripped.

Pros: Rapid volume reduction, community benefit (training).

Cons: Heavy pre-work (testing/abatement), ash/debris still requires cleanup and proper disposal, and approvals can evaporate with a wind shift or air-quality alert. Absolutely not DIY.

If your jurisdiction doesn’t explicitly offer training burns, assume the answer is no and move on.

Comparing Cost-Effectiveness of Methods

Let’s stop squinting and score what actually matters.

- Speed to Gone

- Mechanical: Fast. Hours to a day for typical units.

- Deconstruction: Slow-Medium. Days, depending on salvage goals.

- Implosion: Fast collapse, glacial prep (and rarely applicable).

- Controlled burn: Fast on the day, slow to permit/abate and still cleanup after.

- Cash Out of Pocket

- Mechanical: Moderate. Predictable when access/disposal are known.

- Deconstruction: Low–Moderate net if salvage offsets labor; High if materials are junk.

- Implosion: High. Engineering, permits, insurance, public safety.

- Controlled burn: Variable. Abatement + approvals + post-burn cleanup; sometimes comparable to mechanical when programs exist, often not available.

- Salvage Value

- Mechanical: Low–Medium (if you sort steel/appliances).

- Deconstruction: High (when materials are worth saving).

- Implosion: None.

- Controlled burn: None.

- Permitting Headache

- Mechanical: Low–Medium. Standard demo + ROW/container permits.

- Deconstruction: Low–Medium (same as mechanical).

- Implosion: Max.

- Controlled burn: High and highly conditional.

- Neighbor/Environment Impact

- Mechanical: Noise/dust, manageable with water and planning.

- Deconstruction: Quietest, least dust.

- Implosion: Shock/noise, not neighborhood-friendly.

- Controlled burn: Smoke/ash, air-quality dependent.

- Rule of thumb: If you want one method that balances time, cost, regulation, and sanity, pick mechanical and add selective deconstruction upfront for salvage. If your disposal rates are brutal and the unit has quality components, push further toward deconstruction. If you’re daydreaming about implosion or burning, wake up and call the authority having jurisdiction—they’ll likely say “no,” or “only with abatement, permits, and pros.”

Bottom line

Demolition isn’t a personality—it’s a sequence. Mechanical makes the most projects finish on time and on budget. Deconstruction pays you back when materials and patience exist. Implosion belongs to movies and massive structures, not mobiles. Controlled burning is a fire-department program when allowed, not a hack. Match the method to your site, your rules, and your goals, and the home will do what you want it to do: leave, cleanly, on your timeline—not its own.