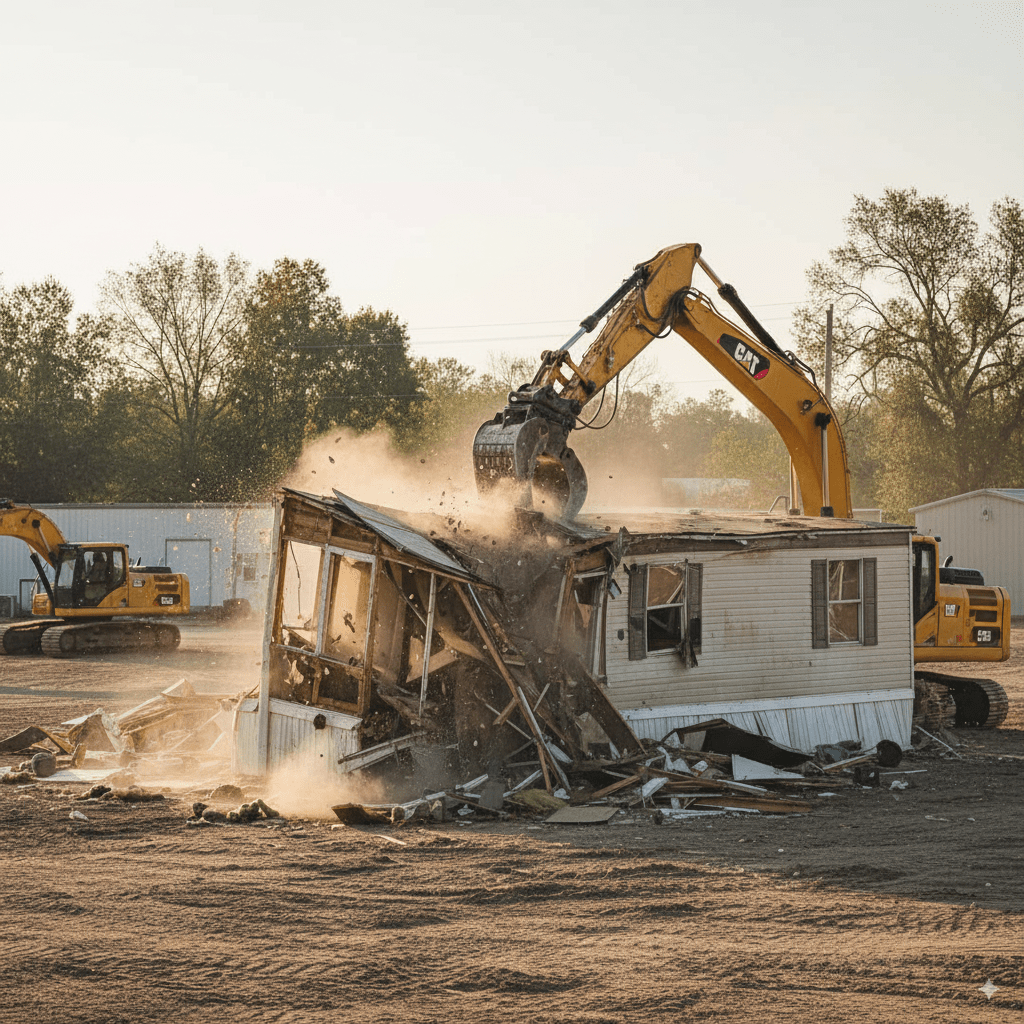

Mobile home demolition services aren’t about making a structure vanish—they’re about navigating a negotiation. Some units come down easily, while others fight every anchor and every dollar. The real cost depends on five levers: size and structure, site access, permits, hazardous materials, and debris disposal. Handle these factors wisely and the job is clean, efficient, and fairly priced. Ignore them, and you risk turning demolition into chaos with added fines.

Size and Structure of the Mobile Home

Cost follows mass and complexity. Bigger unit, bigger invoice; fussier build, fussier day.

- Single-wide vs. double-wide (or triple): doubles mean two rooflines, two chassis sections, twice the seams, and twice the staging. You’re not paying for mystery—you’re paying for labor hours and machine cycles.

- Add-ons change the math: roof-overs, pitched shingle conversions, enclosed porches, carports, skirting upgrades, attached decks—each add-on is a mini-project hiding inside the big one. Roof-overs especially love to hide extra layers you didn’t budget for.

- Foundation and tie-downs: blocks and piers come apart quicker than units bolted to concrete runners or slabs. Steel straps and hurricane anchors are little time thieves.

- Frame and finishes: steel chassis offers scrap value (a modest credit), but wood-heavy, vinyl-clad interiors generate bulkier, pricier loads. Appliances, water heaters, and HVAC units add handling steps if they’re still present.

- Contents: a “furnished” mobile is not a fun surprise. Contents removal can feel like a second job stapled to the first.

Rule you can actually use: scope = length × width × layers. Measure both halves, list every attachment, and make the “extras” explicit on the bid.

Location and Accessibility Challenges

Access either compresses your schedule or expands your bill. Nothing neutral about it.

- Tight parks vs. open lots: narrow lanes, low trees, low wires, and neighbors parked like Tetris blocks force smaller equipment and more hand work. Open acreage lets machines breathe and trailers back in straight.

- Ground conditions: soft lawns, mud, frost, or steep slopes chew up time and plywood mats. You either pay to protect the site or you pay to fix it later.

- Staging and haul route: where do sections land, where do they get processed, and how far to the truck? Every extra 30 feet repeated 200 times is an hour you didn’t plan for.

- Distance to disposal sites: longer hauls mean fewer loads per day and more fuel. If the recycler closes early, late-day loads spill into tomorrow.

- Traffic control: arterial roads, flagging, or street permits can add a line item even if the demo itself is smooth.

Good contractors walk the path, measure gates, check overhead clearances, and show you the load-out plan before a tool leaves the truck. That “slow” setup is how budgets survive.

Required Permits and Regulations

Paperwork isn’t decoration—it’s the guardrail between you and fines.

- Demolition permit: some jurisdictions require one for any structure, others only with utilities or foundations. If a permit is required, it’s required before the first screw squeals.

- Utility disconnects and caps: electric, gas/propane, water, sewer/septic, and telecom lines must be properly disconnected and documented. The phrase “we think it’s off” has burned more money than diesel ever will.

- Park/HOA rules: quiet hours, parking limits, truck routes, and dust control. Ignore them and you’ll meet the person who owns the rulebook.

- Environmental rules: dust suppression for silica, slurry containment if saw-cutting, and proper handling of refrigerants, oils, and batteries.

- Right-of-way permits: needed if you stage dumpsters or machines in the street, or if a section has to cross public space.

Want clarity? Put permits, disconnects, and compliance responsibility in writing in the contract. Adults love assignments with names next to them.

Presence of Hazardous Materials

Hazards change the job from demolition to abatement, and abatement charges by the risk, not the mood.

- Asbestos suspects: old vinyl tile and mastic, ceiling texture, some siding, certain roofing layers, and duct wraps. Testing and removal must be done by qualified folks; guessing is not a management strategy.

- Lead paint: pre-1978 components trigger lead-safe practices, extra PPE, and more careful disposal.

- Refrigerants and chemicals: AC units, refrigerators, freezers, old thermostats (mercury), leftover paints/solvents—all need special handling and paperwork.

- Mold and biohazards: long-vacant units sometimes present with mold, rodent contamination, or worse. That’s not just “ew”—that’s respirators, containment, and slower, safer dismantling.

- Fuel tanks: propane tanks must be evacuated and removed properly. Buried oil tanks turn a simple day into paperwork plus excavation.

Translation: hazards = specialized crew + slower pace + specific disposal = higher cost. The cheapest bid in the room is the one that didn’t look.

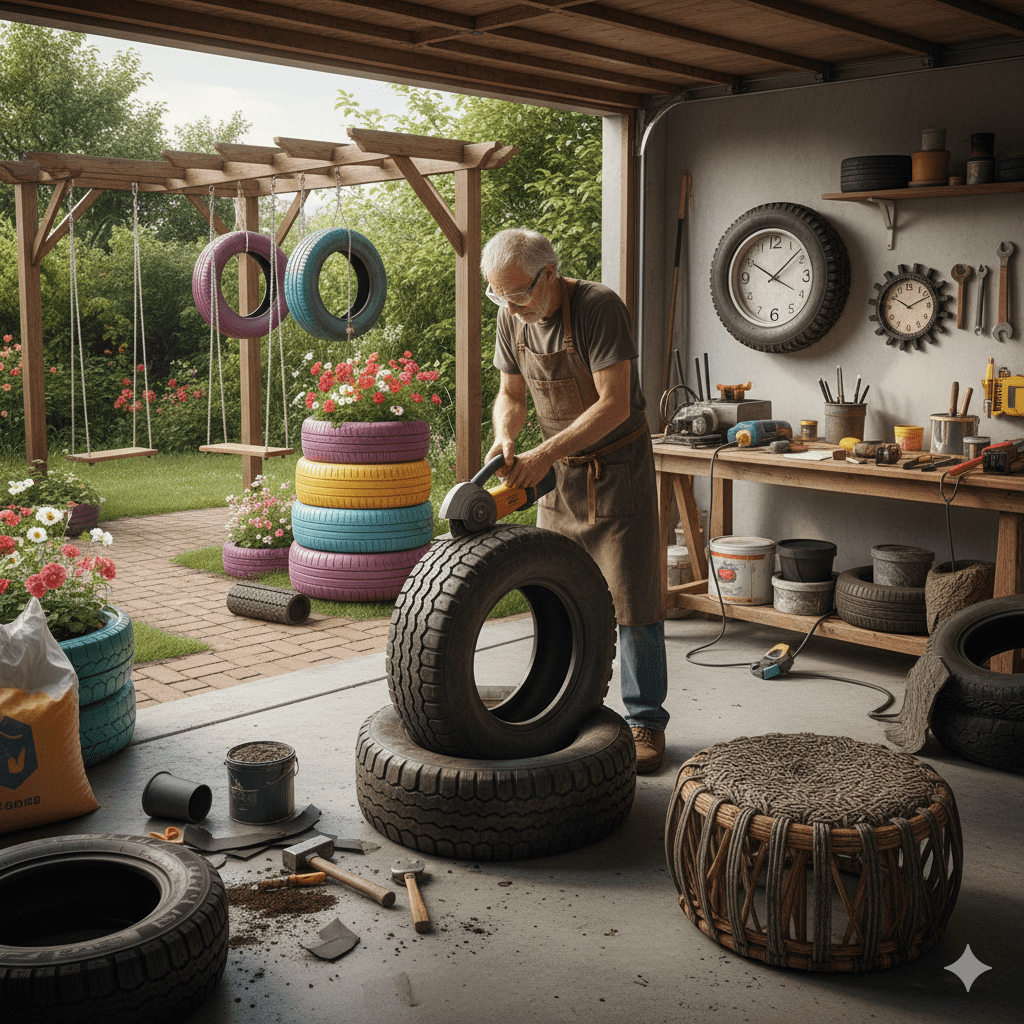

Disposal and Recycling Requirements

You don’t pay to break a mobile home; you pay to make it go away. Disposal is where numbers either behave or mutiny.

- Fee model: facilities charge by ton or cubic yard. Mobile homes are deceptive—light parts, heavy parts, and a lot of air until you compact it. Mixed loads almost always cost more than clean, separated ones.

- Separation saves money: steel chassis and appliances go to scrap; clean wood can have different pricing than mixed C&D; tires, mattresses, and e-waste usually carry surcharges. If the crew sorts on site, you’ll pay labor but often save on tipping.

- Recycler vs. landfill: some regions push recycling with better rates and longer lines; others don’t. The plan should match your local reality, not a blog post promise.

- Number of containers and trips: limited on-site space can force smaller dumpsters and more swaps, which adds haul fees and time.

- Documentation: scale/dump tickets should be attached to the final invoice. Not as decoration—as proof your debris didn’t take a scenic (illegal) route.

If you want the bill predictable, insist on a disposal plan with facility names, expected load counts, and who eats the cost when a load is rejected.

The fast, ruthless pre-quote checklist

Give this to anyone bidding and enjoy the sudden quiet from the pretenders.

- Unit & add-ons: length × width, single/double/triple, roof-over?, porches/decks/carports?, skirting type, foundation type.

- Access & staging: gate width, overhead lines/trees, slope/soil, parking distance to container, haul route.

- Utilities: who schedules disconnects/caps and how documented (photos, receipts).

- Hazard screening: asbestos/lead testing plan, refrigerant recovery, tank removal, chemical disposal.

- Permits & compliance: who pulls, fees included, ROW/dumpster permits, park/HOA rules noted.

- Method & protection: machine type, dust suppression, mats/plywood for surfaces, neighbor protection.

- Disposal plan: facilities, separation strategy, expected containers/loads, surcharge items called out.

- Schedule: start window, daily hours, weather/facility-hours buffers.

- Pricing clarity: fixed vs. T&M, change-order triggers (thickness, hidden hazards, access changes), sign-off process.

- Proof: license, COI naming your address, photos of similar jobs, sample dump tickets.

Bottom line

Mobile home demolition pricing isn’t a magic trick. It’s mass + access + rules + risk + removal. Measure what exists, map the path out, respect the paperwork, treat hazards like real hazards, and send debris where it’s welcome. Do that, and the project ends the way it should: the home is gone, the site is clean, and your budget still recognizes you.