Tires don’t break down—they hang around, collecting heat, breeding mosquitoes, and quietly daring you to pretend they’re harmless. They aren’t. But with the right tech, policy, and incentives, rubber can skip the landfill afterlife and come back as roads, fields, and energy. Here’s the map.

Effects of Tire Waste on the Environment

Abandoned tires are slow disasters with good PR.

- Persistent pollution: vulcanized rubber, steel belts, additives—this cocktail resists decay for decades. Sunlight fractures it into micro-rubber that migrates into soil and waterways.

- Vector hotels: holding water inside sidewalls turns tires into mosquito nurseries and rodent condos—public-health problems with tread.

- Fire risk: tire fires burn hot and long, releasing toxic smoke and oily runoff that’s miserable to contain and worse to clean.

- Heat islands & habitat harm: large piles trap heat, smother ground cover, and disrupt local ecosystems.

- Weight & space: bulky loads eat landfill airspace, and trapped air in whole tires makes them “float” upward, damaging landfill caps.

Short version: tire waste spreads risk across air, soil, water, and time.

Innovations in Tire Recycling Technologies

Rubber’s not trash—it’s feedstock with better engineering.

- Crumb rubber 2.0: high-purity granulation with cryogenic or ambient systems feeds rubberized asphalt, athletic fields, playground surfacing, and molded products with tighter specs and less odor.

- Devulcanization & reclaim: chemical, thermal, and mechanochemical processes break sulfur cross-links, producing rubber that can be blended back into new compounds—lower virgin polymer demand, better performance.

- Pyrolysis with cleanup: oxygen-free thermal conversion yields tire-derived oil, recovered carbon black (rCB), and steel. Modern plants add gas cleanup and quality control so rCB actually replaces virgin CB in tires and plastics.

- Microwave & supercritical approaches: targeted devulcanization with less polymer damage and higher consistency—moving from pilot to commercial scales.

- Smart sorting: AI/vision systems assess casing quality for retreading, lifting reuse rates before recycling even starts.

Tech takeaway: better separation + gentler chemistry = higher-value outputs and real circularity.

Sustainable Alternatives for Used Tires

Not every tire needs a shredder right away.

- Retreading: truck and bus casings get a second (or third) life with new tread—huge material and energy savings vs. new manufacture.

- Engineered civil uses: whole or sliced tires for drainage layers, lightweight fills, retaining-wall backfill, and septic leach fields—designed, permitted, and long-lived.

- TDF (tire-derived fuel): in cement and pulp kilns with strict emissions control; displaces dirtier fuels when local markets lack material outlets.

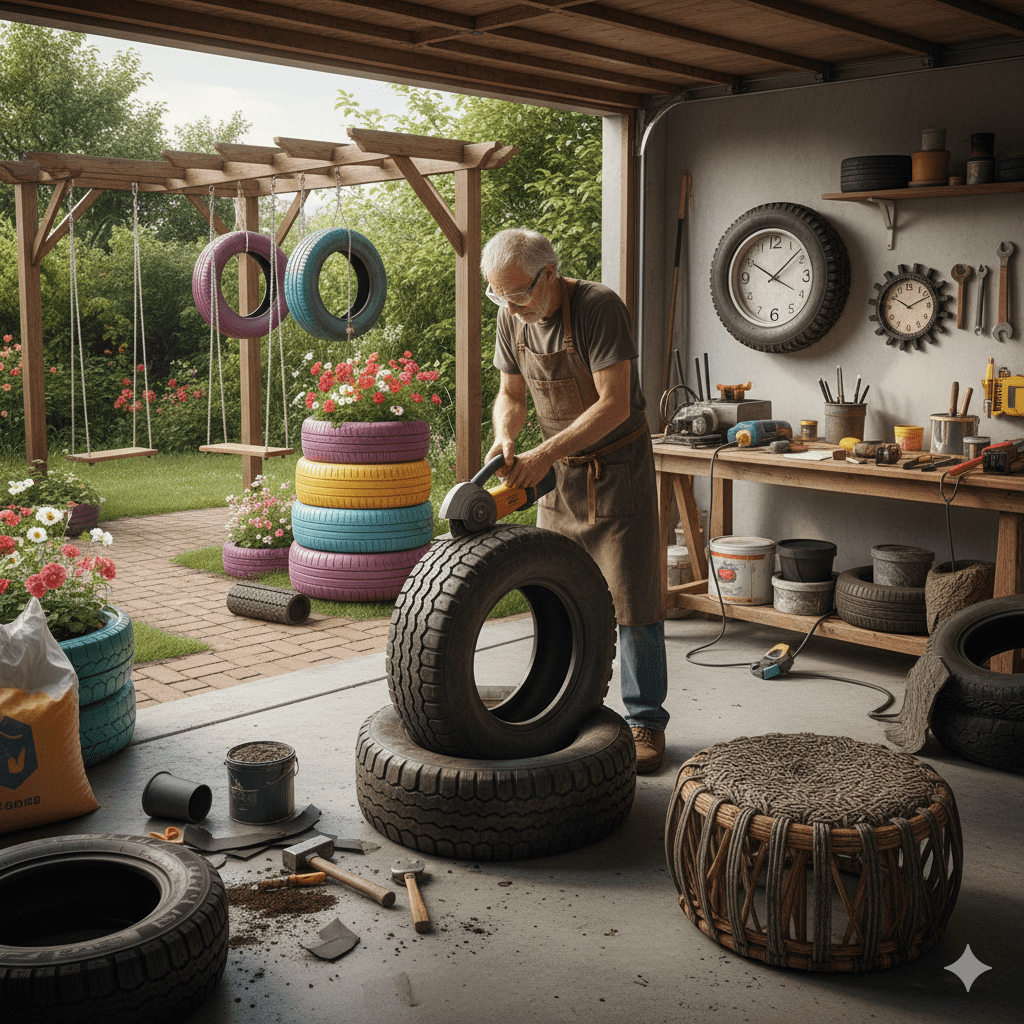

- Community reuse with guardrails: equestrian arenas, playground bases, planters—only where encapsulation, drainage, and leachate controls are specified. Cute is not a strategy.

Hierarchy: reuse > retread > material recycling > energy recovery > landfill (last and rare).

Governmental and NGO Recycling Initiatives

Policy turns good ideas into common practice.

- Scrap-tire fees & funds: small fees at retail finance statewide cleanup, market development grants, and enforcement against illegal dumping.

- Procurement standards: agencies require rubberized asphalt and rCB content in projects, guaranteeing demand so recyclers invest.

- Stockpile abatement programs: coordinated removals with end-market contracts to prevent “move and dump” failures.

- NGO market makers: technical assistance for devulcanization, safety standards for playground surfaces, and community tire-collection events.

- Extended Producer Responsibility (EPR): shifting end-of-life obligations upstream so the system prices in real disposal costs from day one.

Enforcement matters: transporter registration, manifests, and real penalties keep the loop honest.

Incentives for Eco-Friendly Disposal Practices

Money talks; paperwork walks alongside.

- Retailer take-back credits: discounted haul-away when buying new tires; proof of legal disposal included.

- Recycling rebates: per-ton payments for crumb rubber or rCB delivered to approved facilities, favoring high-purity, off-rim loads.

- Contractor bonuses: asphalt bids award points or cash for rubberized mixes; civil projects pay for tire-aggregate use where appropriate.

- Community events: free or low-fee drop-offs that cut illegal dumping—funded by scrap-tire programs, staffed by licensed haulers.

- Tax levers: accelerated depreciation for recycling equipment; grants for devulcanization startups and retread modernization.

Design the incentive, show the receipt, measure diversion. Repeat.

Bottom line

Tire disposal is a choice between slow problems and fast solutions. Without action, rubber lingers, burns dirty, and leaks risk. With professional tire removal services, old tires are routed into modern recycling streams—becoming pavement, parts, and controlled energy instead of waste. Support the system, respect the rules, and those piles turn into infrastructure you can drive on.